Background

For those who may not be acquainted with the process, let’s swiftly review the framework employed for introducing novel features.

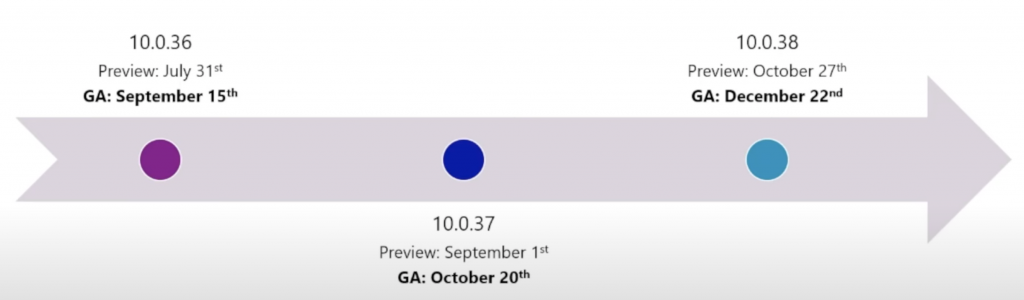

Twice a year, Microsoft Dynamics 365 Supply Chain Management unveils a spectrum of features in two main waves. Wave 1 encompasses versions that achieve General Availability (GA) between April and September, while Wave 2 spans versions reaching GA from October to March.

This mirrors the high-level planning cycle adopted by the product team for releasing innovative features and functionalities. Within these waves, a total of four versions are released annually, a shift from the previous seven, with three versions having been eliminated.

In tandem with this streamlining of service updates, the allowable number of updates that can be paused has been revised from three to one. These modifications will be effective starting in 2024.

Wave 2 Release Timeline

Now, let’s delve into the timeline for Wave 2.

The initial significant release in this wave was 10.0.36, followed by 10.0.37, which achieved General Availability on October 20th. Currently, we find ourselves in the preview timeframe for the culminating release of this wave, namely 10.0.38, slated for General Availability on December 22nd.

The documentation on service update availability has been recently revised to encompass these changes.

Overview

Inventory and Logistics

In the realm of Inventory and Logistics, the latest features offer a comprehensive set of functionalities designed to empower users and streamline operations.

Near Real-Time Inventory Insights:

The introduction of the new Inventory Visibility Power BI dashboard ensures users have access to near-real-time insights into their inventory. This dynamic tool facilitates tracking of inventory management, enables a comparison of supply and demand, provides visibility into product popularity, and aids in making informed decisions about mitigating inventory risks.

Standard Cost for Discrete Manufacturing:

The enhancement to the Global Inventory Accounting add-in allows discrete manufacturing companies to evaluate costs using standard cost practices. This includes the ability to perform parallel inventory accounting based on a single document and utilizing multiple currencies.

Integration with Dynamics 365 Commerce:

A significant stride has been made in integrating Inventory Visibility with Dynamics 365 Commerce. This feature facilitates channel-side inventory availability calculations in near real-time, ensuring holistic accuracy across various channels and locations for retailers.

This integration addresses the previous gap where discrepancies could occur, potentially leading to revenue loss or customer dissatisfaction, especially for retailers using both Dynamics 365 SCM and Commerce.

Mobile App for Inventory Management:

The introduction of a new mobile app for managing inventory in Dynamics 365 Supply Chain Management is a noteworthy addition. This app, set to replace the deprecated inventory on-hand mobile workspace, allows users to check on-hand stock item availability and batch details across legal entities and locations.

The real-time inventory details provided by this app aim to simplify inventory management tasks, enhancing the productivity of both store and field workers.

Compound Charges for Quotations and Sales Orders:

Addressing the complex surcharge requirements in certain industries, this feature adds support for compound surcharges and minimum surcharges for sales quotations and sales orders.

Enhanced Order Processing in Pricing Management:

Noteworthy improvements have been made in order processing within Pricing Management. With enhanced functionality and improved calculation performance, users dealing with relatively simple pricing rules can now work more efficiently by skipping the order completion process. Implementation has also been made more manageable, allowing for a per-company rollout of pricing management.

Additionally, a dedicated workspace in Dynamics 365 Supply Chain Management enables sales managers to view the impact of pricing changes and easily enable and adjust pricing records.

Bundle Sales and Pricing:

Introducing the ability to sell and price multiple items as a bundle, this feature replaces the previous bundle feature that was part of the revenue recognition module and was deprecated in April 2023. This enhancement provides a more robust and streamlined approach to managing bundled product offerings.

Manufacturing & Asset Management

Now, let’s switch gears to latest features in manufacturing and asset management, designed to enhance efficiency and flexibility in operations:

Overpicking for Production and Batch Orders:

Addressing a top-voted idea on the portal, Dynamics 365 SCM introduces the ability to overpick raw materials for production and batch orders using the Warehouse Management mobile app. This empowers workers to meet production demands by allowing controlled overpicking. Warehouse managers can set overpicking thresholds, and workers receive notifications if these thresholds are exceeded.

Material Availability Check for Maintenance Work Orders:

Supervisors now have the capability to conduct a material availability check for maintenance work orders. This process is particularly valuable for organizations ensuring that all required spare parts are available before initiating maintenance work. Leveraging a standard master planning run, this feature calculates the inventory availability of all necessary materials, providing a streamlined approach to maintenance planning.

Dynamic Response to Last-Minute Production Changes:

Dynamics 365 SCM introduces heightened flexibility to accommodate last-minute changes in production. Whether it’s updated items, revised routes, added margins, or scheduling adjustments aimed at optimizing on-hand inventory, the system now seamlessly adapts to changes, ensuring a responsive and agile production environment.

Change Asset Type:

This straightforward feature allows for the modification of the asset type for existing assets. As the name suggests, it provides the flexibility to adjust the categorization of assets according to evolving organizational needs.

Modify Functional Location Types:

Dynamics 365 SCM now supports the change of functional location types for existing assets. This feature enables organizations to adapt and optimize their asset management strategy by adjusting the functional location types to align with evolving operational requirements.

Planning, Procurement & PIM

Demand Planning App for Dynamics 365 Supply Chain Management:

Introducing the Demand Planning app, a cutting-edge solution that represents Microsoft’s Next Generation collaborative demand planning initiative. Powered by state-of-the-art forecasting algorithms and models, this app offers an immersive user experience along with intelligent reports and analytics. Designed to empower organizations in building agile, resilient, and sustainable demand planning practices, this app redefines the approach to demand modeling and planning configuration. It seamlessly enables on-the-fly aggregation and disaggregation, fostering intelligence-driven collaboration within the organization.

Prioritizing Existing Supply in Planning Optimization:

Tailored for make-to-order businesses, this feature allows the configuration of coverage groups to prioritize existing supply over required Bill of Materials (BOM) or route specifications. By considering BOM or formula versions and routes specified in demand lines, such as sales order lines, when creating supply (such as planned production orders), this feature enhances planning optimization for a more streamlined and efficient process.

Vendor Communication on Shipping Dates:

Enhancing communication with vendors, Dynamics 365 SCM introduces a new ship date field in purchase orders, calculated based on configured transport dates. When master planning suggests a date for placing a plan order, the system now takes into account transportation day setups. This ensures goods arrive at the designated location on time, optimizing the overall supply chain timeline.

Managing Compliance with Export Control Restrictions:

The latest feature in Dynamics 365 Supply Chain Management focuses on compliance with export control restrictions. This functionality allows organizations to effectively manage, track, and verify compliance before confirming, packing, shipping, and invoicing sales orders. By utilizing a native data warehouse solution interfacing directly with the supply chain management instance, organizations can seamlessly enforce and manage export control policies, ensuring adherence to regulations.

Warehouse Management

Finally, the set of features related to warehouse management:

Dynamic Printer Selection:

Introducing dynamic printer selection, this feature enables the system to automatically choose a printer based on the current work user, warehouse location, and/or zone when a worker requests printing. Warehouse Managers can set up default printers for each work user, warehouse location, or zone, streamlining the printing process and ensuring optimal resource utilization.

Integration with External Order Management Systems:

Dynamics 365 SCM now supports the operation of warehouses connected to external order management systems. This integration enhances the overall flexibility and adaptability of warehouse operations, ensuring seamless coordination with external systems for a more synchronized and efficient workflow.

Warehouse Mobile Devices Workspace:

The Warehouse Mobile Devices workspace provides a centralized hub to monitor the health and license status of all handheld devices used within the warehouse. This feature enhances visibility and control, allowing for proactive management of devices to ensure uninterrupted warehouse operations.

Automatic Document Updates for Purchase Orders:

Streamlining the receiving process, users can now run the “receiving completed” process to indicate the conclusion of registration for a specific inbound load. This feature optimally captures a packing slip ID and document date, ensuring accurate and up-to-date documentation for received purchase orders.

Serial Number Confirmation during Picking:

Serial confirmation during picking allows workers using a mobile device to confirm the accurate picking of serial numbers. This feature adds an extra layer of validation to the picking process, reducing errors and enhancing accuracy in managing serialized inventory.

Work User Session Query Range Utility Tool:

Adding functionality to aid workers in finding specific records, this utility tool is introduced for setting up queries within the Warehouse Management mobile app. The tool enhances the efficiency of workers by facilitating targeted searches and quick access to relevant records during warehouse operations.