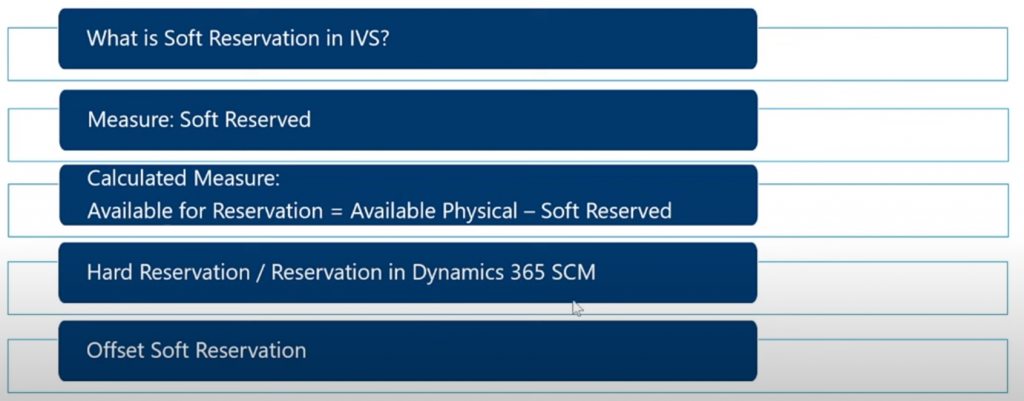

In the realm of Dynamics 365 SCM, the soft reservation feature has undergone notable enhancements within the Inventory Visibility Service (IVS). Before delving into these advancements, let’s take a moment to refresh our understanding of the terminology associated with this feature.

Soft reservation, a fundamental concept within the Inventory Visibility Service, facilitates the reservation of a quantity for a product upon the receipt of an order. For instance, when an order is placed via an e-commerce website, the request can be promptly relayed to IVS to soft reserve the specified quantity. It’s termed ‘soft’ because it doesn’t directly reserve inventory in the Dynamics 365 SCM ERP, which serves as the primary input source.

Subsequently, the e-commerce order is synchronized with Dynamics 365 SCM, where hard reservation and offset reservation processes take place. However, during this interim period, the soft reservation capability within IVS ensures an accurate depiction of available inventory on hand.

To leverage the soft reservation feature in IVS effectively, two key measures are typically configured. Firstly, a physical measure designated as ‘soft reserved’ is established. This measure tracks the quantity soft reserved for orders and furnishes insights into the current soft reservation status.

Secondly, a calculated measure is set up in IVS, often referred to as ‘available for reservation’. This measure indicates the quantity of a product available for soft reservation upon order receipt. It is computed as the available physical quantity minus any existing soft reservations.

Upon synchronization of orders from the e-commerce website to Dynamics 365 SCM, the ordered quantity undergoes reservation within Dynamics 365 SCM, known as hard reservation. Concurrently, the offset of the soft reservation is triggered from Dynamics 365 SCM to the Inventory Visibility Service.

Enhancements in Soft Reservation

In the recent release of Microsoft Dynamics 365 Supply Chain Management version 10.0.33 and beyond, a significant enhancement has been introduced – the ability to make soft reservations directly from sales orders. This new functionality streamlines the reservation process by posting reservation requests to Inventory Visibility and validating available-for-reservation quantities within the system.

Soft reservations play a pivotal role in establishing a unified source of truth for available inventory, particularly throughout the order fulfillment journey.

Organizations operating with at least two distinct systems for outbound order processing benefit greatly from soft reservations. It ensures that inventory is not double-booked, mitigating the risk of overselling when multiple systems attempt to reserve the last available stock simultaneously. With instant soft reservation API calls to Inventory Visibility, organizations attain a singular, reliable source for inventory availability.

Soft reservation functionality encompasses several key operations, illuminating its efficacy in inventory management:

- Initial Inventory Sync: Commencing with the synchronization of initial inventory levels from Microsoft Dynamics 365 Supply Chain Management to Inventory Visibility.

- Reservation Posting: Soft reservations are posted from each order channel or system to Inventory Visibility. Here, inventory availability is validated, and soft reservations are attempted. Upon successful reservation, Inventory Visibility increments the soft reserved quantity, decrements the available-for-reservation (AFR) quantity, and furnishes a unique soft reservation ID.

- Inventory Integrity: Despite soft reservations, the physical inventory quantity remains unchanged.

- Sync and Reservation Conversion: Subsequently, either individual or aggregated soft-reserved orders (order lines) are synced with Supply Chain Management to facilitate hard reservations. These reservations are pivotal for warehouse allocation or updating final inventory quantities.

- Offset Mechanism: Organizations have the flexibility to configure the system to offset soft reservations upon updating physical inventory in Supply Chain Management.

The creation, consumption, and cancellation of soft reservations are predominantly orchestrated through API calls to the Inventory Visibility service. This streamlined approach ensures operational efficiency and accuracy in managing inventory reservations.

Data Storage in IVS

The methodology of data storage plays a pivotal role in optimizing performance and facilitating seamless inventory operations. Traditionally referred to as data storage rules or partition rules, these mechanisms dictate how data is organized within the IVS cache.

Historically, IVS mandated that each change operation, whether it be soft reservation, inventory modification, or allocation API requests, necessitated the specification of a warehouse. This approach aimed to enhance performance by grouping data and distributing it across different instances, thereby minimizing access times.

Recognizing the need to accommodate scenarios where inventory operations extend beyond warehouse boundaries, a groundbreaking enhancement has been introduced. Enter the new set of data storage rules: By Product IDs.

With this evolution, IVS now offers two distinct storage rule options:

- By Warehouse: The conventional method involves grouping data based on warehouses. However, with the advent of the By Product IDs approach, this method no longer serves as the primary means of locating data for inventory change operations.

- By Product IDs: The newly introduced storage mechanism revolutionizes data organization by grouping it according to product IDs. Unlike the warehouse-centric approach, the By Product IDs method offers enhanced flexibility, allowing users to execute inventory operations seamlessly, irrespective of warehouse boundaries.

It’s important to note that the selection of data storage rule—whether By Warehouse or By Product IDs—is a global setting that remains static once the system is live. Consequently, swapping between these mechanisms post-implementation is not feasible.

Should the need arise to transition to the By Product IDs storage rule, a comprehensive data cleaning process is required, followed by the re-synchronization of data from scratch. This ensures a seamless transition while maintaining data integrity and operational continuity.