We have already briefly touched on engineering change management – so don’t forget to check it out (should you have missed it). Now, let’s move to the Product Change Process with ECM and its business process.

Product Change Process

Once a product has gone through the initial launch, we likely will need to make changes throughout its life cycle. Normally, updates are driven either by a periodic process (reviewing product offerings and determining whether we need to make changes), or they may come up ad hoc.

For instance, a customer service agent may get a call from a customer requesting an adjustment to the Bill of Materials.

Once there is a change request, a team dives into an investigation to determine whether the change is feasible and what the implications are. Project management and accounting module may be used should a change be way too complex. It will help to track the cost of the research or test runs in production.

Then, if we decide to approve the change – we will create the change documentation in the form of a change order to track changes and various approvals we want to capture for that change.

We also will also analyze the business impact of the change and identify any ‘on-hand’ or ‘work-in-progress’ inventory of the upcoming obsolete version.

Once change approvals are completed, we can release the updated product information to the manufacturing entities – just like we did for the new product launch.

Change Impact

Now, let’s dig deeper into a key decision to make when you are processing a product change. The rule of thumb used by many organizations is the F-3 rule, which stands for Form, Fit, and Function:

- Form refers to the physical aspects of your product, like size, shape, or weight;

- Fit refers to the product’s ability to connect or join with other parts in an assembly;

- Function refers to the purpose of the product.

The F-3 rule essentially says that if we see a change in the form, fit, or function of an item – it should be a new item or variant.

ECM for Process Manufacturing

First things first, you need to have two main features enabled: Engineering Change Management and Manage changes to formulas and their ingredients. These features can be turned on through the feature management module.

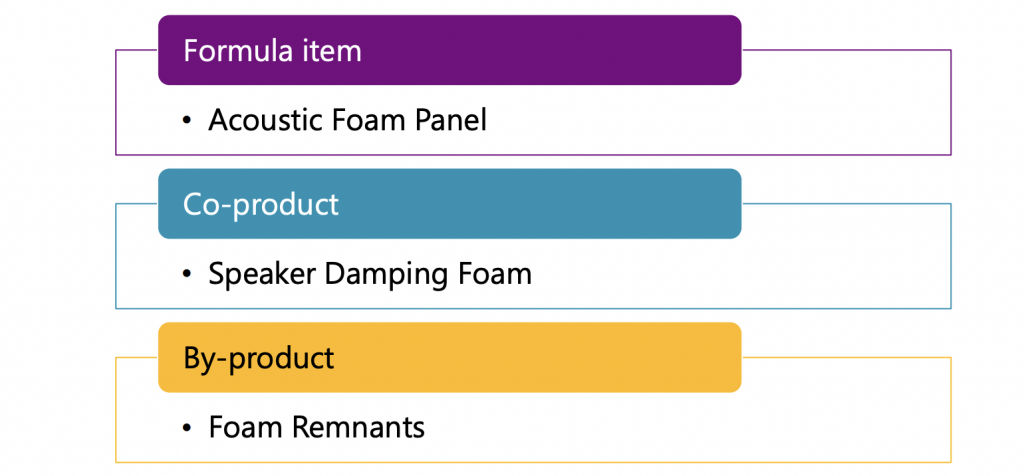

Then, when we create engineering products, the only options allowed by the system for product categories are production types of BOM formula or Planning items. That means co-products, by-products, and raw materials which have a production type of ‘none’ will typically be set up as regular release products (or not as engineering products).

The intent here is to use ECM to control the changes to the formula in route. Any item that’s not the main formula item does not need to be ECM enabled.

Example Scenario

Let’s say there is ABC Audio which has a process manufacturing facility, that makes acoustic foam panels that are used in speaker production. And, we want to control the process using engineering change management.

In this case, the formula item, which is our acoustic foam panel, will be set up as an engineering product. Because it has the formula and the route attached to it. Then, the co-product speaker damping foam will be set up as a regular product, meaning non-engineering. And finally, the by-product foam remnants will also be set up as a regular product and not an engineering product.

Change Request & Change Order

Now that we have reviewed the product change process as well as the setup and configuration required for an engineering product produced using the manufacturing process – let’s delve into change request and change order.

Typically, an organization will build processes around the change request and change orders to change the engineering products using the ECM.

Change Request

The engineering change request process lets you capture requests for changes from all the relevant departments in your company. It does not matter whether you work in the engineering, sales, or manufacturing departments – anybody can use engineering change requests to request a change.

A change request can suggest a product change, although it will not happen until the change is approved. This change might be an idea for a new product and issue you discovered while working with an existing product or a suggestion for improving an existing one.

Finally, once someone submits a request for a change, the review and approval process can be managed by a workflow that identifies who must approve the change. It can be a product manager or a product owner.

Change Order

Engineering change orders provide a structured process for making changes to engineering products. Typically, a product manager is the one who initiates the change order process. He proposes changes by using the engineering relevant data and creates engineering change orders from scratch. Or, if a change request is approved, a product manager can convert the change request into the change orders.

You can define attributes such as priority and severity for change orders as well as for change requests. In addition, you can define attributes like customer approval, material disposal codes, etc.

Finally, you are able to include multiple products on a single engineering change order using change new product, new variant, or new version. Once change is approved and processed, the product can be released to the operational company.